[ad_1]

A legacy of European-built and operated space modules, which began in Earth orbit and is now heading for the moon, got its start 40 years ago this week.

From the first launch of Spacelab, a pressurized laboratory that rode in the payload bay of a NASA space shuttle, on Nov. 28, 1983, to Columbus, one of the main modules of the International Space Station, to I-Hab, an element of the Artemis Gateway station to be deployed in lunar orbit in the coming years, all have a common heritage — hardware that was built and assembled in Europe.

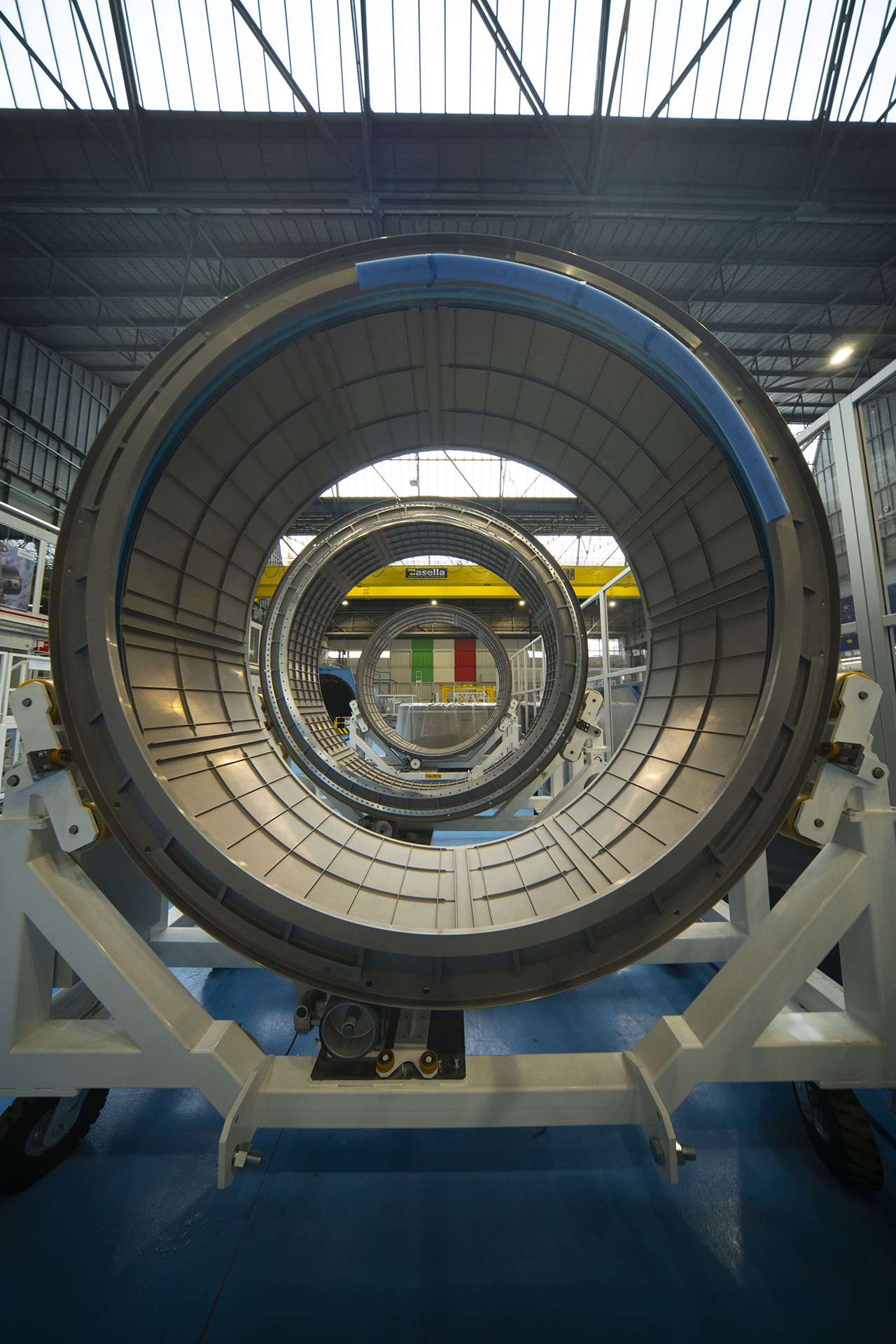

“The industrial legacy of Spacelab is clear,” stated the European Space Agency (ESA) in a feature article published on its website on Tuesday (Nov. 28). “The companies involved have changed names several times since the 1970s, but pressure shells are still being machined from space-grade aluminum-copper alloy 2219 in Turin, Italy in premises run today by Thales Alenia Space.”

Further integration work is today done in an Airbus Defense and Space facility in Bremen, Germany, the same halls that were used to bring together Spacelab four decades ago.

Related: Spacelab: Space Shuttle Flew Europe’s First Space Module 30 Years Ago

Airtight assemblies

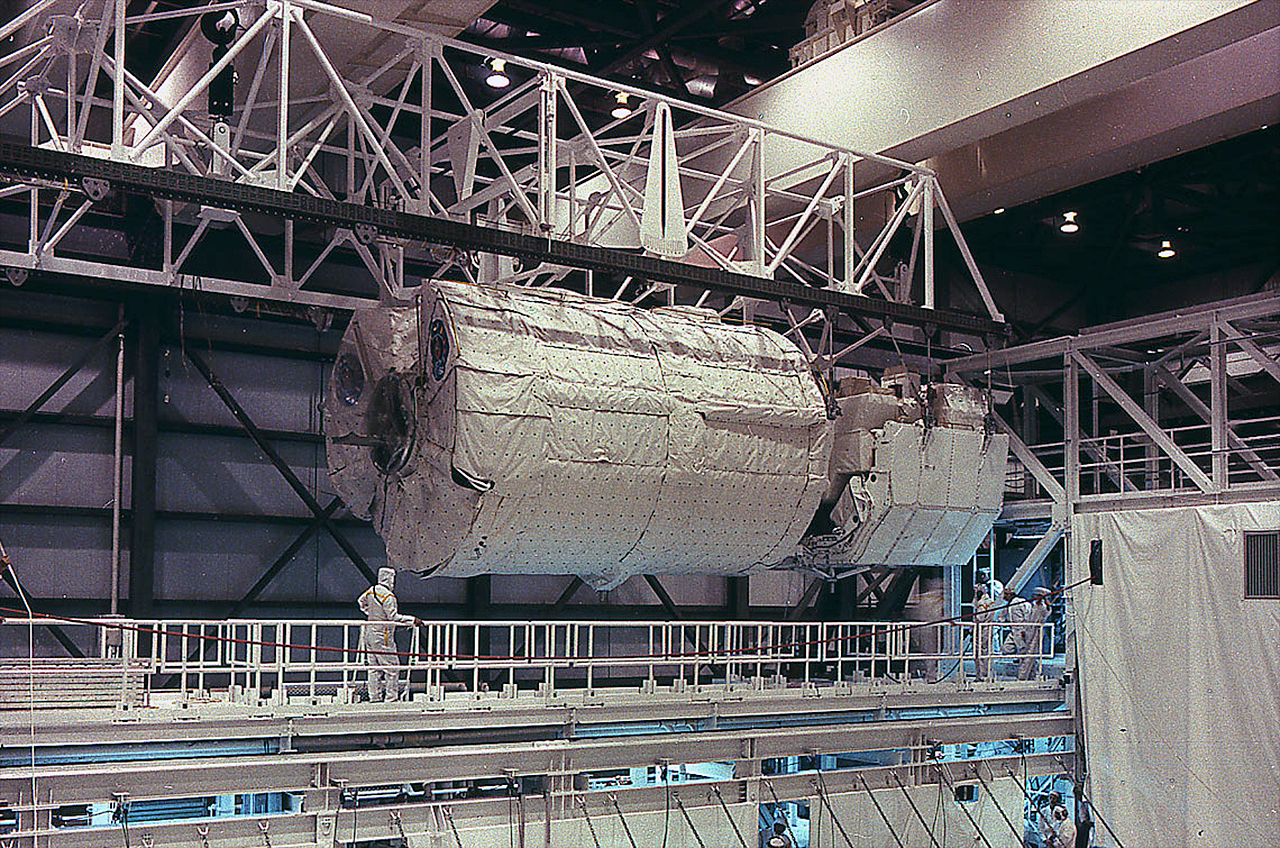

The first Spacelab mission that launched on board space shuttle Columbia supported 72 science experiments, which were conducted during the 10-day STS-9 mission. That 22-foot-long by 13.5-foot-wide (6.7 by 4.1-meter) module, like the ones that followed for the shuttle and later programs, were designed to keep the external vacuum of space at bay.

Like Spacelab, the Columbus module and other major “rooms” built for the International Space Station in Europe were constrained in size by the dimensions of the shuttle’s cargo hold, whereas I-Hab will measure just 26 by 10 feet (8 by 3 meters) as driven by the capability of its launch vehicle.

“Gateway elements might be smaller than previous European modules but should also be stronger,” said Joao Gandra, a materials and processes engineer with ESA. “The big difference is that — as with Europe’s latest Axiom and Cygnus pressure shells — they are now welded using ‘friction stir welding,’ which softens rather than melts metals, applying friction to join them together. While traditional welding can impart stresses into joints, this technique results in stronger welds with improved performance.”

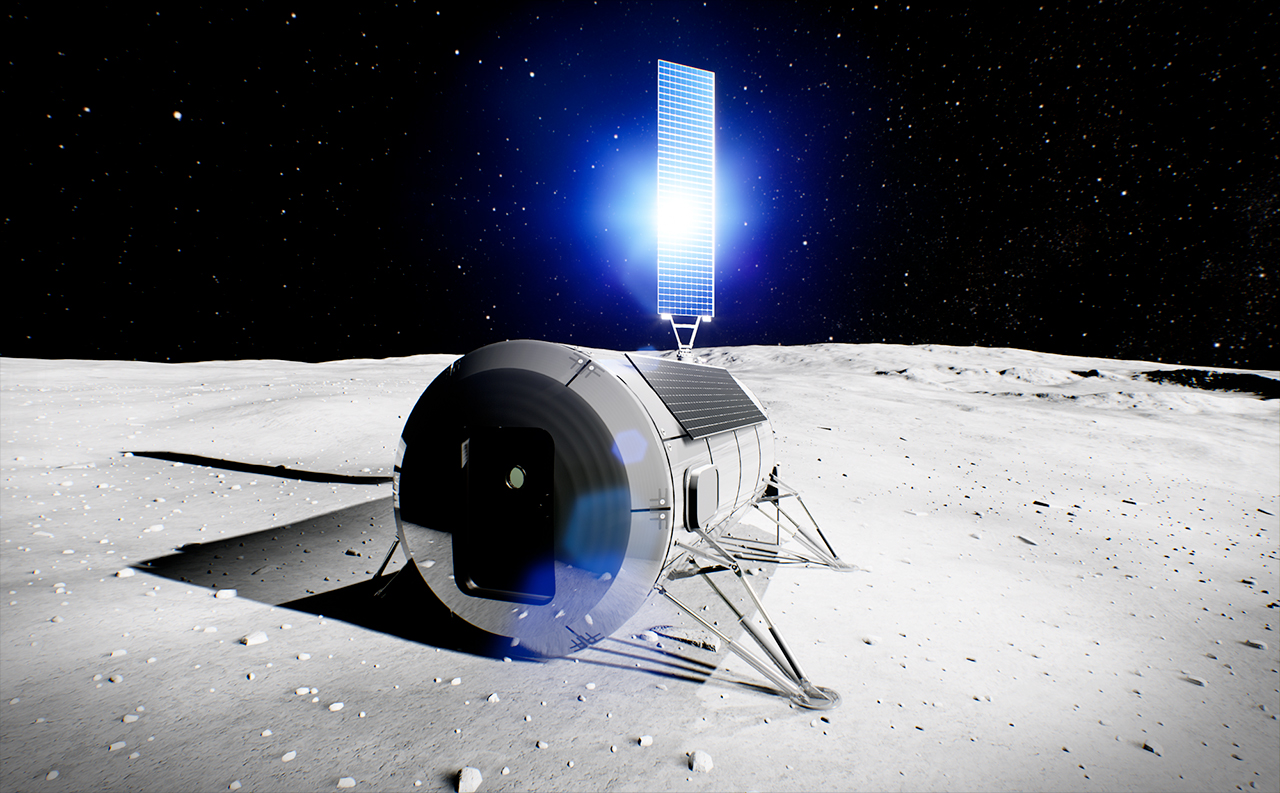

The I-Hab will serve as living quarters aboard the multi-module Gateway for crews of four for up to 30 days at a time. Is is slated for launch in 2028.

Developed for all directions

As compared to Spacelab, I-Hab’s designers had the challenge of fitting all of its necessary systems into a smaller habitable volume, including scientific equipment, cooking facilities and four sleeping stations.

“Previous ISS modules – like Spacelab before them – were designed with an up and down orientation just because astronauts find that easier to work with. With I-Hab we don’t really have that luxury, because we need to make use of all available space as efficiently as we can, while at the same time fulfilling all human factor and crew-performance-related requirements,” said Mark Wagner, ESA’s lead for the Lunar Gateway Baseline, Verification and Assembly, Integration and Testing Team.

Like Spacelab, which was only used when the space shuttle was in orbit, Gateway will only be human-tended. It will not a continuous crew like on board the International Space Station.

As such, I-Hab will not be equipped with a toilet; the crew will use the one board NASA’s Orion spacecraft for that. And early expeditions will need to come equipped with their own water, food and other consumables, which is one of the reasons that missions will be limited to 30 days, in addition to limiting the astronauts’ exposure to deep space radiation.

ESA is planning for I-Hab to have the same “shirtsleeves” working environment that was first engineered for Spacelab and the ISS modules, with a 72 degrees Fahrenheit (22 degrees Celsius) temperature and 50 percent humidity, although the atmospheric pressure will be 0.7 atmospheres compared to the sea level pressure that prevails on the station, helping drive down I-Hab’s total mass.

“Despite being smaller, I-Hab will be more inclusive in the sense we are designing for 99 percent astronaut accommodation, meaning almost all the very smallest female astronauts to the biggest male astronauts will be able to operate equipment easily and comfortably – such as opening hatches or rapidly disconnecting fluid lines – compared to an equivalent 95 percentile figure for the ISS,” said Wagner.

The return of Spacelab?

I-Hab’s development has passed through its Preliminary Design Review (PDR) and is currently in its detailed design phase. This latest example of a European crewed module has a design lifetime of 15 years, although using the ISS modules as an example, it is likely that I-Hab will go on operating for much longer.

Based on the current plans for Gateway, eventually more than half of the lunar orbit outpost will be European in origin.

Europe’s original Spacelab module template could also make a comeback. A contract recently signed between the Italian Space Agency ASI and Thales Alenia Space includes designing Spacelab-size modules to be deployed on the lunar surface to become part of a future moon base.

[ad_2]