[ad_1]

COLORADO SPRINGS — Max Space wants to help humanity expand into the final frontier.

The startup is developing a range of inflatable space habitats, the largest of which could provide as much internal volume as a sports stadium. These plans, which Max Space unveiled on Tuesday (April 9) here at the 39th Space Symposium, are designed to help our species make the difficult leap off its home planet.

“The problem with space today is, there isn’t enough habitable space in space,” Max Space co-founder Aaron Kemmer said in a statement on Tuesday. “Unless we make usable space in space a lot less expensive, and much much larger, humanity’s future in space will remain limited.”

Related: Living on the moon: What it would be like (infographic)

Back in 2010, Kemmer co-founded the off-Earth manufacturing company Made In Space, which has sent multiple 3D-printing devices to the International Space Station (ISS) over the years. (Made In Space was acquired by Redwire in 2020.)

He says that experience helped convince him that expandable habitats are the future, citing one of the machines Made In Space modified for use on the ISS.

“It’s like a three-story system on Earth, and all the engineering wasn’t to make it work in space — it was actually to get it down to a locker [size], just because there wasn’t enough real estate in there,” Kemmer told Space.com in an interview here at the symposium on Tuesday.

Expandable habitats, as the name suggests, launch in compressed form to fit inside rocket fairings but increase in size greatly when deployed in space. They therefore offer much more bang for the buck volume-wise than traditional “tin can” module designs.

An expandable habitat with 100 cubic meters (3,530 cubic feet) of pressurized volume, for example, would be “at least an order of magnitude cheaper” than a comparable metallic one, Kemmer said. (For perspective: The ISS offers 388 cubic meters, or 13,700 cubic feet, of habitable volume, not including the space provided by visiting vehicles.)

This is not a sci-fi concept; three expandable module prototypes are actually circling Earth right now. They are Genesis 1 and Genesis 2, which are free fliers that launched in 2006 and 2007 respectively, and the Bigelow Expandable Activity Module (BEAM), which has been attached to the ISS since 2016.

All three were built by Nevada-based company Bigelow Aerospace, which closed its doors in 2020. The pressure-restraining hulls for Genesis 1 and Genesis 2 were designed and manufactured by Thin Red Line Aerospace, a small Canadian company run by Maxim de Jong — Max Space’s other co-founder.

The new startup, which has been in operation for about a year, is commercializing Thin Red Line Aerospace technology, Kemmer and de Jong said. But that tech isn’t just a Genesis retread.

“It’s a very, very, very different approach, where you’re just putting fibers in an uncoupled scenario where they don’t conflict with one another,” de Jong told Space.com on Tuesday. The result, he and Kemmer said, is a cost-effective module that expands in a predictable and reliable way, and is highly scalable to larger sizes.

The new tech will get its first off-Earth test just two years from now, if all goes according to plan: Max Space has booked a spot on a SpaceX rideshare launch in 2026.

That mission will send a module the size of two large suitcases to orbit. However, that’s the habitat’s compressed configuration. Once deployed, it will expand to a pressurized volume of 20 cubic meters (706 cubic feet).

This deployment will set a new record for expandable habitats. The two Genesis prototypes both feature 11.5 cubic meters (406 cubic feet) of internal volume, while BEAM has 16 cubic meters (565 cubic feet).

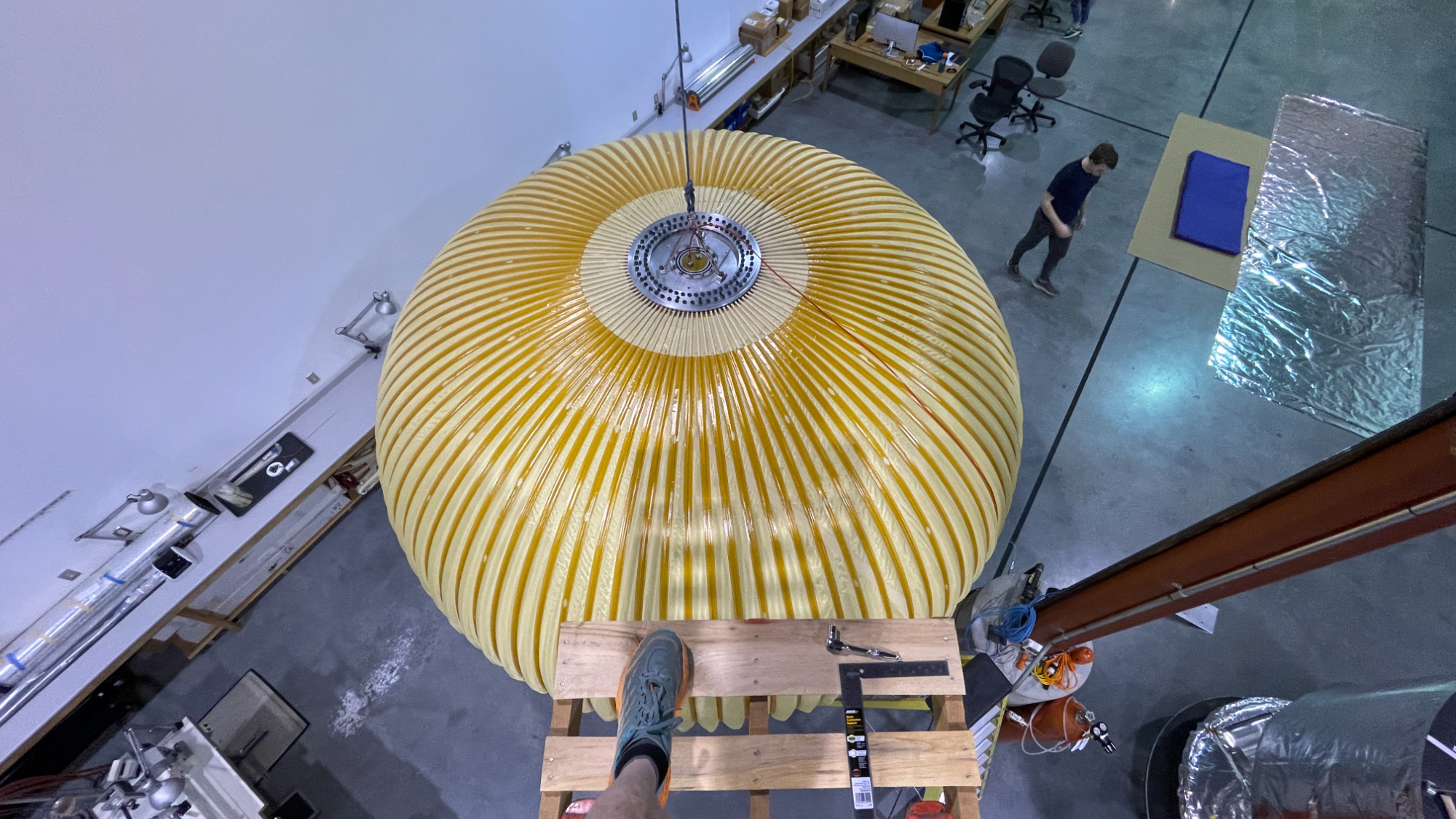

Max Space has already built a full-size prototype of the first flight unit, which the company is using for ground testing, Kemmer said. It has started manufacturing the flight vehicle, which will not feature life-support systems but will have the same shielding and strength as human-rated versions.

Related: NASA’s moon-orbiting space station will be claustrophobic, architect says

Max Space plans to keep moving fast after this pioneering module makes it to orbit. The startup aims to launch its first 100-cubic-meter (3,531 cubic feet) module in 2027 and to get a 1,000-cubic-meter (35,314 cubic feet) behemoth up by 2030. Even larger variants could potentially launch thereafter, aboard SpaceX’s Starship megarocket or Blue Origin’s New Glenn vehicle, the company said.

The goal is to provide a variety of destinations to a range of customers, from pharmaceutical companies that want to mass-produce medicines in microgravity to commercial space stations that want to expand their living space all the way to movie studios looking to film in orbit.

“We have several space production companies that we’re talking to,” Kemmer said. The company has already secured some customer contracts, including from the U.S. Space Force, he added.

But Earth orbit will be just the starting point for Max Space modules, if all goes according to plan.

“My dream is to have a city on the moon before I die,” Kemmer said. “So I look at this like, this is going to be the habitat, the structures, that are going to go inside the lava tubes buried under the [lunar] surface.”

The company’s modules would then make their way to Mars, if all goes well, for Max Space wants to be a key enabler of off-Earth settlement. Indeed, that’s why Kemmer and de Jong founded the company — to help humanity extend its footprint out into the solar system.

“That was the entire reason,” Kemmer said.

[ad_2]