[ad_1]

Tackling the issues: Electronic waste is a growing problem. Each year, consumers produce millions of tons of used and broken electronics. Only a portion of the metals they contain are recycled because reclamation is expensive, cumbersome, and can’t keep up with the volume of discarded devices. Sadly, the rest is either burnt or buried in landfills, and neither option is environmentally friendly.

Recently, scientists developed a sponge created from a waste product of cheesemaking capable of absorbing metals from electronic waste. The study published in the January edition of Advanced Materials notes that the organic material is particularly efficient in sucking up gold, so much so that it can retrieve $50 worth of gold for every dollar spent on the recycling process.

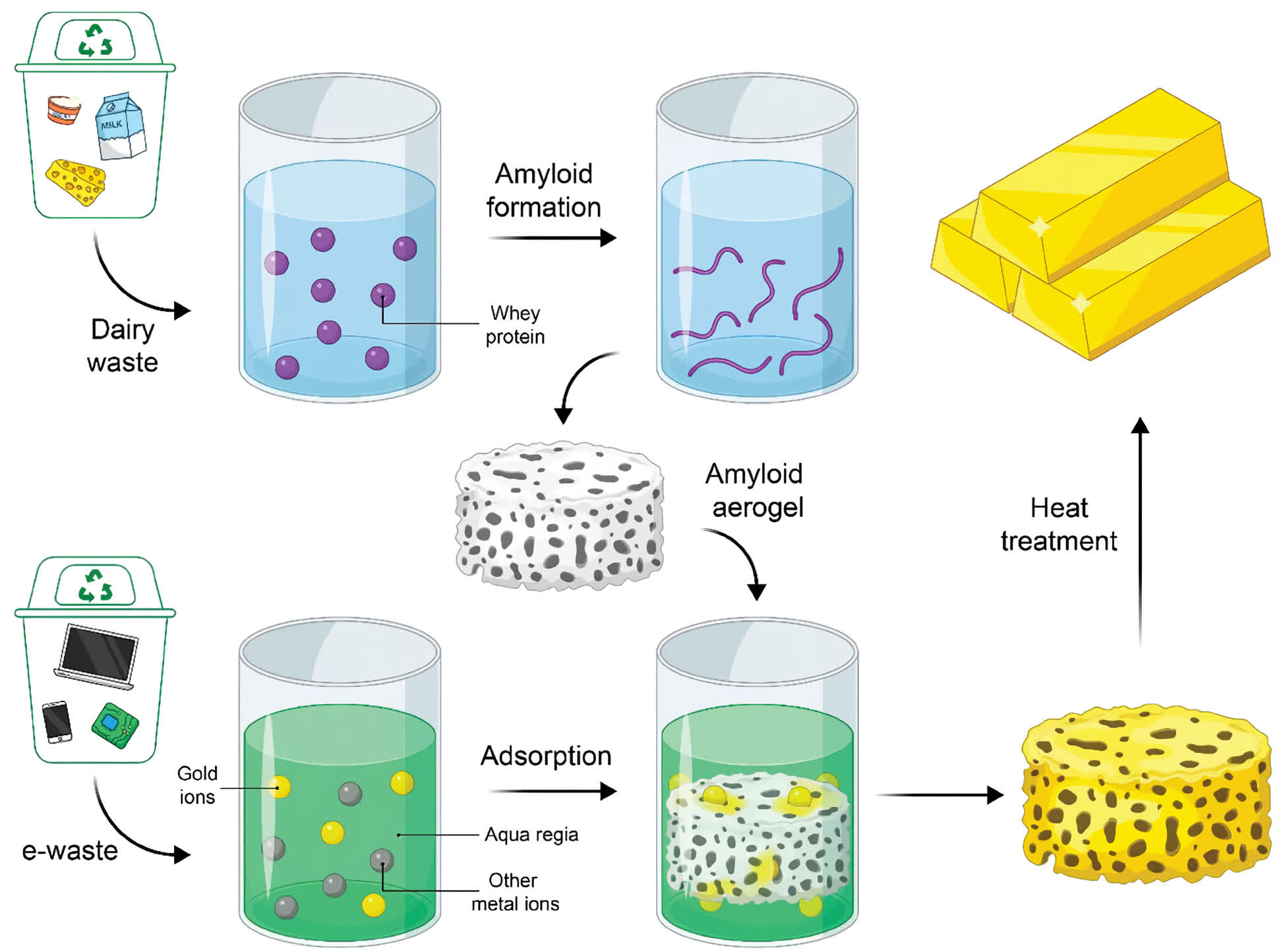

The method starts with whey, a harmless dairy byproduct produced when making cheese. The scientists first denature the dairy proteins by heating the whey in an acid bath. This step creates the amyloid nanofibrils used to form the sponge. The electronic components are then dissolved in acid to create an ionic solution rich in gold and copper.

When added to the ionic solution, the protein sponge attracts the metals which adhere to it. The sponge is heated again, turning the ionic metal into gold flakes. The flakes are then easily removed and melted into nuggets. In tests, the scientists extracted 450mg of 22-carat gold – about 91 percent gold and 9 percent copper – from 20 used motherboards.

Although less environmentally harmful than e-waste, diaries dispose of well over 100 million tons of whey annually, according to the National Institute of Health. If the electronics recycling industry adopted this method of gold extraction, dairies could potentially sell their waste whey instead of paying to dispose of it. The irony of using a waste product to recycle valuable material for another waste product is not lost on the scientists.

“The fact I love the most is that we’re using a food industry byproduct to obtain gold from electronic waste … You can’t get much more sustainable than that,” said Raffaele Mezzenga, ETH Zurich professor and co-author of the study.

Business Insider notes that as of 2023, some recyclers are making as much as $85,000 daily by extracting gold and copper from electronic components. Using the sponge is more efficient and could increase recyclers’ margins.

Unfortunately, we have seen this before. In 2021, Canadian scientists developed a patented but similar technique for extracting gold from discarded electronics. However, an exclusive partnership with the Royal Mint prevents the extraction method from wide distribution.

Mezzenga said that his team wants to commercialize their process and sell it to the e-waste industry but doesn’t have a time frame for getting it done.

[ad_2]